Using the wide range of stencils options available, a simple metal etching system can be used to easily mark both short run and larger volumes of ID tags with marking that is permenently etched into the surfce of the metal.

If the equipment that required the identification plates is made from metal and is unpainted, further cost-savings are possible by eliminating the tags altogether and etching the information directly onto the part.

TO START:

You will require a suitable metal etching system and some consumables. The correct type of etching system depends on how large an area needs printing, as the more information needs etching the more powerful the etcher needs to be to etch consistently.

Etching the ID tag's fixed information

Although tags can be pre-printed in bulk by a printer, this is not always suitable for etching smaller volumes. Our Permanent Stencils can be pre-printed with all the required fixed information such as company logos and empty "data fields" which can later be filled in with the required variable information.

Permanent Stencils are high-resolution and are re-usable thousands of times over.

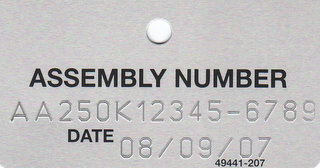

1. Etch fixed information and leave all data fields blank to be filled-in later

2. Etch fixed information, some data fields & leave some data fields blank

Etching ID Tags Variable Information

There are a variety of different ways we can etch the variable information on the pre-printed tags. The right choice depends on how many fields you must fill in and what sort of information must be printed.

1. Etch serial-number/date using variable numbering stencil

Simply change the last strip to advance to the next number. We can achieve alpha-numeric numbering as long as the letters and numbers occur in the same sequence ie :ABC123, ABD124

Simply change the last strip to advance to the next number. We can achieve alpha-numeric numbering as long as the letters and numbers occur in the same sequence ie :ABC123, ABD124

2. Etch single-lines on plate with portable stencil printer

Type in what data is required on one line of the ID tag and press "print" - your stencil is created and can etch 4-5 times. Any combination of alphanumeric text/numbers can be printed one one line in various sizes. Each line must therefore be etched as a separate process.

Type in what data is required on one line of the ID tag and press "print" - your stencil is created and can etch 4-5 times. Any combination of alphanumeric text/numbers can be printed one one line in various sizes. Each line must therefore be etched as a separate process.

3. Multiple lines of data with dot-matrix printer and fibre stencil paper

Using a dot-matrix printer and computer, you can print the required variable data from any program - (such as Word and Exel) onto stencil paper, which you can then use to etch the ID plates.

Using a dot-matrix printer and computer, you can print the required variable data from any program - (such as Word and Exel) onto stencil paper, which you can then use to etch the ID plates.

4. Etching entire ID plate with all information

It is possible to design the entire plate, both fixed (including logos) and variable information, using the dot-matrix printer and a computer. This is ideal for totally customised one-offs as the design can be totally changed to suit. Overall quality is limited to the quality of the dot-matrix printer and the stencil paper - not as sharp as the "permanent stencil" but still presentable.

It is possible to design the entire plate, both fixed (including logos) and variable information, using the dot-matrix printer and a computer. This is ideal for totally customised one-offs as the design can be totally changed to suit. Overall quality is limited to the quality of the dot-matrix printer and the stencil paper - not as sharp as the "permanent stencil" but still presentable.

Other marking alternatives.

The other alternatives to etching the variable information include pinmarking systems and laser marking systems, as per the pinmark sample below. These systems are better suited to higher production volumes.