Identify your products with a simple coloured dot

The Dotmark is a compact, reliable and easy to install ID marking system, printing a single dot to indicate the product has undergone a process, passed/failed a test inspection, originates from a particular production line or a simple orientation/installation mark.

Compatible with variety of inks

The Dotmark uses a printhead with a compact high speed

valve designed to run a variety of inks.

These include

- Pigmented Inks

- Dye-based inks

- Methyl Ethel Keytone based ink (MEK)

- Alcohol based ink

- Water based ink

- Custom inks (such as non-toxic)

Simple and easy bracketry for installation

Ink is supplied to the printhead via the ink reservoir, pressurised using the integrated air-pump (or optionally through plant air).

The supplied mounting bracket and hardware provides a flexible solution to installation in any application.

As the machines are so lightweight - making your own custom mounting brackets to suit your own application is extremely simple.

User serviceable, reliable and low maintenance

The self-contained controller will operate at 110VAC and 220VAC and offers easy adjustment of dot-size, burst-rate and burst time.

The Dotmark is user-serviceable and operates with low maintenance for a cost-effective, simple and reliable ID marking alternative.

Maintenance usually involves purging the unit before a shift to flush the dried ink from the front of the nozzle, which is also an ongoing process during periods of inactivity.

Fully Featured

- Prints at up to 600 dots per second

- On non-porous or porous surfaces

- On moving or stationary objects

- Simple and easy to use

- Selection of different ink colors

- User serviceable

- Customisable

Complete Package

- Print Head

- Controller

- Power Supply

- Ink Supply System, 1Liter

- Air pump

- Optical Sensor Trigger

- Mounting Equipment

Printing Modes

The Dotmark controller is able to control the printhead differently upon receiving a print signal, printing single dots, or spraying a "burst" of dots adjustable in frequency.

-

Single shot mode: produces a single dot when the unit is triggered.

-

Continuous mode: produces a “line” of dots as long as the trigger is active.

-

Burst mode: produces a line of dots that can be adjusted in length.

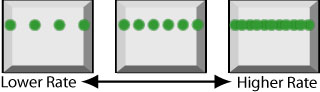

The rate at which the dots are fired is adjustable for both the Continuous mode as well as the Burst mode.

-

Dot printing rate adjustable Lower to Higher

Related Information:

| Attachment | Size |

|---|---|

|

Dotmarker systems used for coloured ID dot marking

|

97.78 KB |

|

User operation manual for dotmark system

|

526.7 KB |